![hat-filtresi-kapak[1]](https://inoksprom.com/wp-content/uploads/2024/02/hat-filtresi-kapak1.jpg)

![hat-filtresi-1[1]](https://inoksprom.com/wp-content/uploads/2024/02/hat-filtresi-11.jpg)

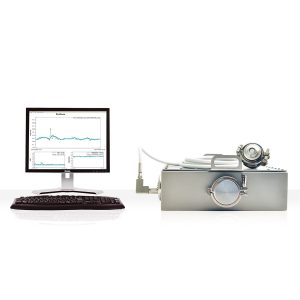

Stainless Milk Line Filter

- Description

- Reviews (0)

Description

Stainless Milk Line Filter; It ensures the removal of undesirable substances, usually of visible size, that are contaminated from liquids or gases due to different reasons. It has different pore sizes depending on the product to be filtered; these pore sizes can vary between 100 microns (0.1 mm) and 2000 microns (2 mm). Filters used in the food industry; It is made entirely of stainless steel to ensure hygienic conditions.

Inoksprom Stainless Milk Line Filter; These are the equipment used to clean the raw milk that has just arrived at the milk purchasing unit from coarse dirt before cooling/storage.

During the milking or transportation process, as a result of farm conditions and other environmental factors; It may be exposed to undesirable pollution factors such as straw and chips. Not only is this a hygienically harmful situation; At the same time, it reduces the performance of process equipment such as plate heat exchangers, pasteurizers, homogenizers and pumps, causes blockages and shortens part replacement processes.

Therefore, the first process that should be applied to the milk reaching the enterprise should be filtering.

Stainless Milk Line Filter; It has two different designs: Line Filter and Bag Filter .

Inoksprom Line Filters ; These are units with filters made of stainless steel or hygienic fabric placed inside the main body. Since it does not require any disassembly/assembly process in the pipeline, it offers an advantage in terms of ease of use.

Filtering area inside the filter body; It is produced in varying pore sizes depending on the product to be filtered. For dairy products, this size is preferred as 500 microns. The milk flowing in the pipeline enters the filter body and is directed into the filtering area. While liquid milk flows easily through these pores, pollution factors with particle sizes over 500 microns cannot pass through the pores and are retained in the filter.

After a certain period of time, in order to prevent clogging of the filtering surface as a result of the accumulation of the pollution factors in question, the filter is removed and cleaned at regular intervals in a few seconds, and it is easily replaced again.

In Single Line Filters , milk flow must be temporarily interrupted during filter cleaning. In high capacity enterprises where there is a constant milk inflow ; By choosing Duplex Line Filters, there is no need to interrupt the milk flow even for a short time during cleaning.

Duplex Line Filters also have double filtering zones, therefore double filters. Milk flow is directed towards one of the filters with the diverter valve. If clogging occurs on the filter surface after a certain period of time; The milk flow is directed to the other filter through the valve; and there is no need to stop the milk flow while the clogged filter is cleaned and replaced.

Reviews

There are no reviews yet.