![foss-profoss-kategori[1]](https://inoksprom.com/wp-content/uploads/2024/02/foss-profoss-kategori1.jpg)

![ProFoss™-1[1]](https://inoksprom.com/wp-content/uploads/2024/02/ProFoss™-11.png)

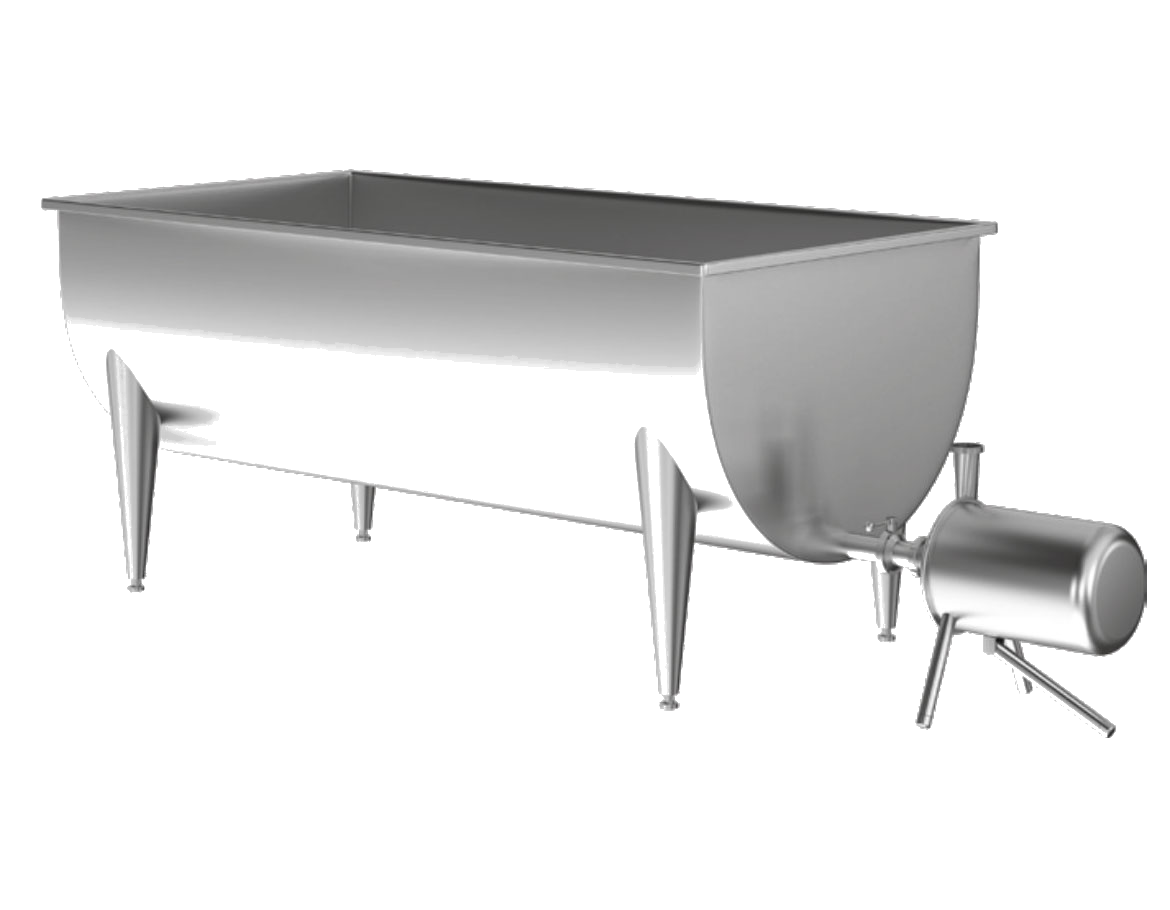

ProFoss | In-Line Rapid Milk Analysis System

- Description

- Reviews (0)

Description

Possibility to analyze Cheese, Whey Powder, Butter, Yoghurt, Milk Powder online during the production phase.

NIR technology specially designed for online use in the production line

Online analysis of Fat, Moisture, Dry Matter parameters during production

Possibility to study new parameters thanks to smart calibration development software

ProFoss™ feed milling system is based on NIR high resolution diode array technology, providing non-destructive analysis, directly in the process line without bypass. The analyzer is housed in a robust cabinet. Results can be fed into your production/SCADA system and/or be presented on a screen in the production area for rapid adjustments of your process. Precise instrument matching enhances method development, minimizes implementation efforts and ensures calibration model transferability between analyzers.

Streamline your production with High Resolution in-line analysis

Achieve complete control of your feed production with Pro- Foss™ in-line sensor. Follow product composition more closely with a continuous flow of “real time” measurements of main animal feed parameters, such as moisture, protein and fat, using high resolution diode array technology. Installing ProFoss™ after the mixer enables you to validate target parameters and make timely adjustments to meet specified final product quality.

Improve your business with accurate control

Profit opportunities are waiting to be found in your feed production process. For instance, protein and moisture optimization, reducing variability and producing closer to target will lead to considerable cost savings and a fast return on investment.

Users of such solutions report a rapid return on investment with a typical payback time of less than twelve months.

A advantages of dairy powder process control include im¬proved yield and profit based on:

Optimized moisture content

Run production closer to specified targets

Consistent product quality

Higher value products for your customers

Increased energy efficiency

Reduced rework

Anyone can use it

With its user-friendly and low maintenance features, ProFoss™ gives your production staff the perfect tool to maintain process control for increased yield and improved consistency. Near infrared, high resolution technology ensures a high level of accuracy that you can rely on day in day out.

ProFoss | In-Line Rapid Milk Analysis System

Anyone in the plant can contribute to process control. Easy-to-use calibration software options such as ISIcal™ allow non-experts to develop or expand existing calibration with automatic sample synchronization. Once calibrations have been made, there is no need for further adjustments.

Quick and simple to implement

The High Resolution technology behind the accuracy of the ProFoss system also has benefits when implementing the system. Because measurements can be relied on to be the same across individual instruments and are highly stable over time, you can reduce the time and money spent on installation of individual analyzers. The standardization and stability of the solution, as well as the intelligent FOSS calibration tool ISIcal™, makes it fast and easy for non-experts to develop or expand calibrations and transfer them across units.

Reviews

There are no reviews yet.