![plakali-esanjoru-kapak[1]](https://inoksprom.com/wp-content/uploads/2024/02/plakali-esanjoru-kapak1.jpg)

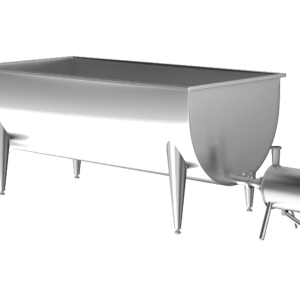

Milk Cooling Exchanger

- Description

- Reviews (0)

Description

What is an Exchanger?

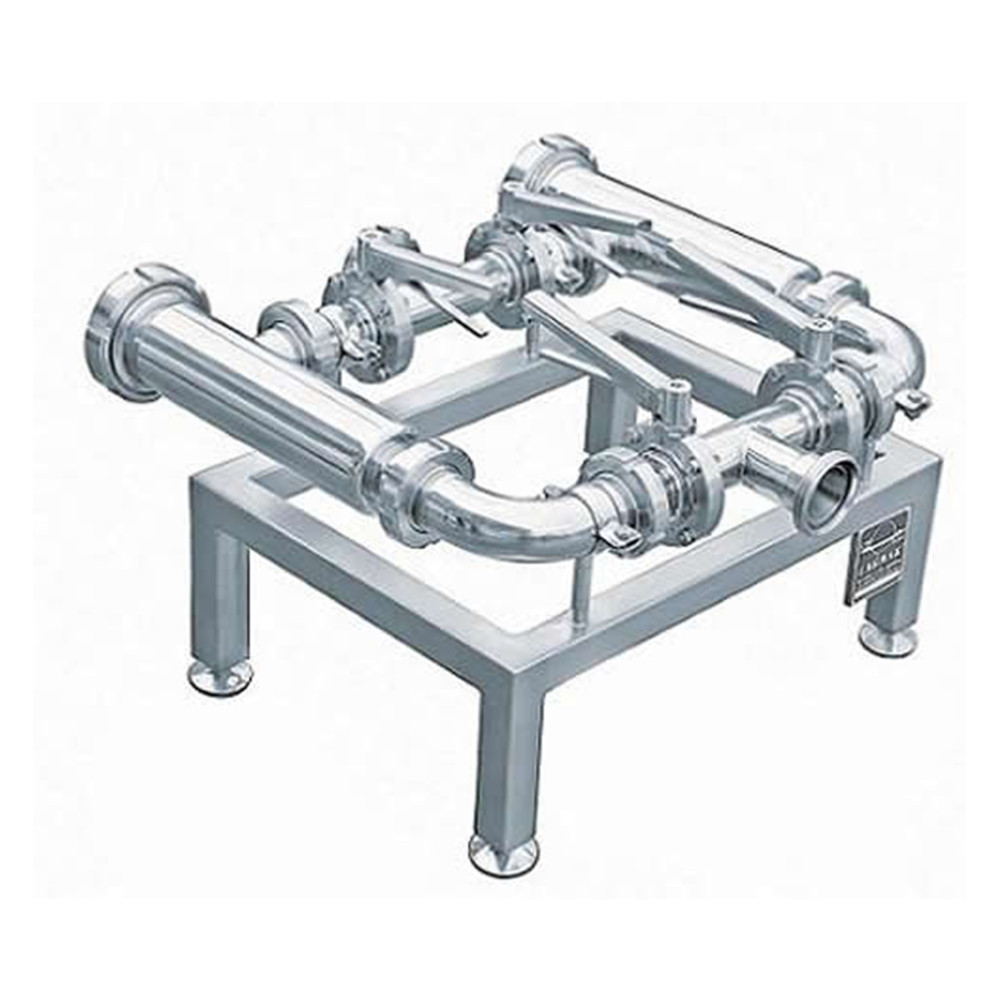

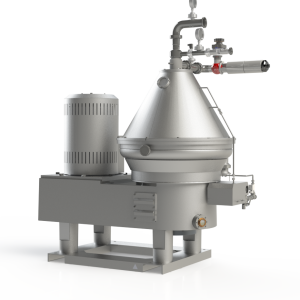

Plate Heat Exchangers; They are heat transfer equipment designed to heat/cool fluids at different temperatures by exchanging heat over plate surfaces without contacting each other.

When designing plate heat exchangers , the inlet temperature values, flow capacities and desired outlet temperature values of the main media to be heated or cooled and the heater/cooler media are the determining parameters. While one of the fluids fed to the exchanger is heated and its temperature increases, the other one cools down by losing heat in the same way.

The fluids fed to the Milk Cooling Exchanger are directed through gaskets, preventing them from directing to the same plate gap. They do not contact each other and only flow in a downward or upward direction between consecutive plates, while bringing one surface of the plate they contact to the same level with their own temperature, and the second media flowing on the other surface of the same plate. It absorbs the liquid transferred to this plate because it is in contact with the plate surface during flow.

Factors that determine the number of plates in the Milk Cooling Exchanger design; The temperature difference and flow rates between the two fluids. Heat exchanger size and number of plates required to cool the same amount of milk with ice water at 1 C; It is smaller than the heat exchanger designed with 5 C ice waterLikewise, the flow rates of two fluidsare another determining factor in heat exchanger design.

Heat Exchanger Plate Designs

The components that provide heat transfer in the Milk Cooling Exchanger are the plates. Therefore, the desired output temperature values to be achieved within unit time are determined by the number of plates, plate design and plate correlation . The speed of the liquid flowing on a completely flat plate surface is different from the speed of the same liquid flowing on serrated plate surfaces with different correlations. This elementdirectly affects the contact time of the fluids with the plate surface, thus the heat transfer time and dT (difference between inlet and outlet temperatures) value.

Plate Heat Exchangers are the component plates that provide heat transfer. Therefore, the desired output temperature values to be achieved within unit time are determined by the number of plates, plate design and plate correlation . The speed of the liquid flowing on a completely flat plate surface is different from the speed of the same liquid flowing on serrated plate surfaces with different correlations. This elementdirectly affects the contact time of the fluids with the plate surface, thus the heat transfer time and dT (difference between inlet and outlet temperatures) value.

Heat transfer

The amount of heat transfer that will occur in Plate Heat Exchangers varies depending on the combined effect of the following factors:

Streaming Speeds of Media

Physical Properties of Media

Temperature Profile

Predicted pressure drop

Heat Exchanger Design

Plate Surface Contamination Rate

Predicted cleaning/sanitizing frequency and duration

Plate Surface Coordination

choreography; Plate Heat Exchangers are the name given to plate surface designs applied to increase the heat transfer rate of heated or cooled fluids during flow and to balance the flow rate on the plate surfaces.

Form of choreography; It provides turbulent flow to the liquid moving between the plates. Rather than moving on a flat surface with a constant heat transfer coefficient, a more stable heat transfer occurs thanks to the turbulence that occurs, and the dT value, which is the difference between the inlet and outlet temperatures of the media, increases.

Plate Surface Contamination

Foods are sensitive to heat, at varying levels depending on their chemical composition. In high temperature applications, some components in the food tend to precipitate and cause layers to form on the plate surfaces.

During heating of fluid milk at temperatures of 90 C and above; The whey protein contained in milk is denatured and clings to the surface of the plate because they are more sensitive to heat. In these cases, the layers must be cleaned with a correct CIP protocol. Otherwise, as the heat transfer area will decrease, the heat exchanger performance will decrease and energy consumption will increase. Apart from this, there will be contamination in the fluids that continue to be fed to the exchanger.

Plate Material

Plate heat exchangers used in the Food Industry are manufactured from AISI316 stainless steel to ensure hygienic conditions. Plate thicknesses ranging from 0.5 mm to 0.7 mm are preferred depending on the type of product to be processed.

Although it is not necessary to use titanium materials in product applications such as Brine Water and Whey with high acidity, it is a common practice to use titanium materials in order to prevent the plate surface from being worn and punctured or exposed to other damages.

While thick plates are preferred in Plate Heat Exchangers in order to increase the service life of the exchanger plates, it should also be taken into consideration that the heat transfer coefficient will decrease to a certain extent, thus more energy will be consumed to achieve the same parameters.

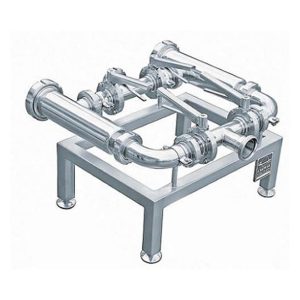

Plate Heat Exchanger Components

The main components that make up Plate Heat Exchangers are;

plates

Exchanger Body (Movable Body/Fixed Body)

Gaskets

Body Shaft

Heat Exchanger Feet

Input/Output Connections

can be listed as.

Plate Heat Exchanger Application Areas

Plate Heat Exchangers; As we have stated, these are units used to transfer heat between liquids without touching or mixing with each other. In the food industry, the production and preservation of foods suitable for human consumption are essential practices in terms of both health and operating economy, high efficiency, standard product quality, and these processes are provided through Plate Heat Exchangers .

The main usage areas of Plate Heat Exchangers are;

Dairy Industry

Plate Milk Cooling Exchangers

Plate Milk Pasteurizer Designs

Plate Cream Pasteurizer Designs

Plate Brine Pasteurizer Designs

Plate Yoghurt/Buttermilk Cooling Exchangers

Fruit Juice Industry

Honey Pasteurizer Design

Ketchup/Mayonnaise Production

Alcoholic/Non-Alcoholic Beverage Industry

Jam Production

Vinegar Production

Sunflower Oil/Olive Oil Industry

Vegetable Oils

Syrup Preparation Units

Sauce/Pure Production

Reviews

There are no reviews yet.