![otomatik-seperator3-png-1[1]](https://inoksprom.com/wp-content/uploads/2024/02/otomatik-seperator3-png-11.png)

Milk Cleaning Clarifier

- Description

- Reviews (0)

Description

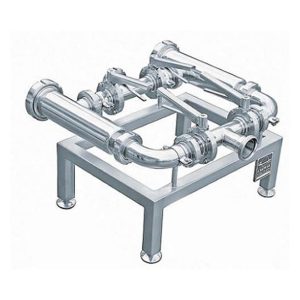

Inoksprom Milk Cleaning Clarifier; It is a centrifugal separator configured as a clarifier for milk and whey, with a centripetal pump, capable of automatic partial and full discharge, and suitable for cleaning in place (CIP).

Inoksprom Milk Cleaning Clarifier can be delivered as a skid unit, mounted on the platform and with the wiring completed to its own panel.

APPLICATION

Inoksprom Milk Cleaning Clarifier; Specially designed for milk and whey cleansing.

Its purpose is to remove organic and inorganic solids/pollutants contained in milk and whey. It is also effective in somatic cell cleansing and spore reduction.

Inoksprom Milk Cleaning Clarifier; can also be used to recover precipitated protein from whey

FEATURES

Inoksprom Clarifiers are new generation separators designed especially for the dairy industry.

While the product is gently processed under high hygiene conditions, maximum efficiency is achieved thanks to advanced features;

• High drum speed; It creates high centrifugal force thanks to quality materials and engineering.

• Discs; Large diameter discs arranged closely together provide a wide separation surface.

• Specially designed feeding pipe; Feeding system that gently accelerates product feeding, minimizing shear stress and foaming.

• Valve discharge mechanism; It ensures fast and precise discharge and reduces the loss of milk and valuable components (protein, fat).

• Centripetal pump outlet with back pressure valve; It ensures high efficiency milk cleaning by regulating the separation.

• Hygienic structure; It is provided with quality materials, polished discs, surface treatments applied to product contact surfaces to prevent product residues and optional CIP system.

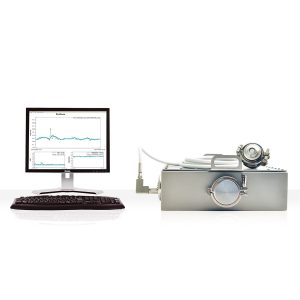

• Simple drive and use; With the lowest possible energy consumption without friction lining, VFD is used for soft starts and stops, PLC is used for automatic control of centrifugal separation and CIP, and HMI is used to set operational parameters and control alarms.

• Stable lower body; Stainless steel coating applied over heavy cast iron.

• Skid unit; Easy to install and ready to work .

Clarifier Working Principle

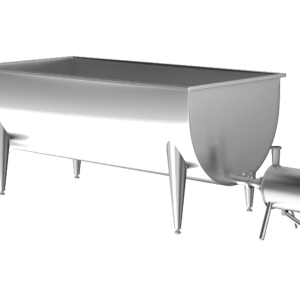

The product is fed into the drum where it undergoes separation under centrifugal force. Centrifugal force

ensures the separation of solid contaminants and milk according to the density difference. The milk is forced to flow through small spaced discs that allow separation of smaller solid particles.

The cleaned milk overflows from the drum towards the centripetal pump and is taken out of the separator under pressure with the help of the centripetal pump. The back pressure valve on the outlet pipe can be adjusted to regulate the liquid load inside the drum.

Heavy solid particles accumulate on the outer wall of the drum and

are discharged out of the separator through partial and/or full discharge processes at periodic intervals. During the partial discharge process, only the solid volume is discharged, while in the full discharge process, the entire drum volume is discharged.

Partial and full discharge frequencies can be adjusted via the HMI interface with PLC control software.

Reviews

There are no reviews yet.