![DHC-CATEGORY[1]](https://inoksprom.com/wp-content/uploads/2024/02/DHC-CATEGORY1.jpg)

![Homogeniser-with-Cooling-KATEGORI[1]](https://inoksprom.com/wp-content/uploads/2024/02/Homogeniser-with-Cooling-KATEGORI1.jpg)

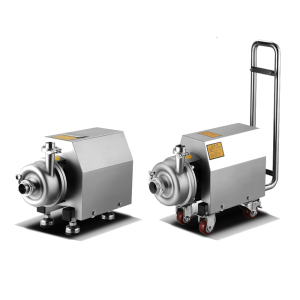

Mixer Pump

- Description

- Reviews (0)

Description

| Usage | Continuous connection to the process line or circulation with a balance tank |

| Purpose of usage | Disintegrator, Emulsifier/Disperser/Homogenizer |

| Area of Use | Food, Pharmaceutical and Cosmetics Industry |

| Working Principle | On-Line High Shear Mixer Pumps installed on the process flow line; They are integrated in order to disperse/emulsify and homogenize different phases that have the ability to dissolve in each other, either in continuous flow or in circulation through the mixing tank.There are no more than 1 to 3 rotor/stator gear pairs in the emulsion region. The rotor starts to rotate at high speed thanks to the powerful motor it is connected to; It carries out the function of quickly shredding and tearing the material by taking it into the emulsion circle. Particles that remain under this effect are rapidly dispersed, broken down and emulsified until their sizes are reduced to a minimum. |

Homogenizer Pump Advantages

- Mass production with continuous working principle

- Saving time and energy

- Minimizing the quality difference between batches

- Equal distribution and emulsion at every point of the output product

- Easy to use and maintain

- Automatic control

Scope of application

- Food industry

- Chemical/Petrochemical Industry

- Biopharma Industry Single Stage High Shear Mixer Pumps

- Cosmetics Industry

- Detergent Process

| Mixing/Dissolving | Emulsifying soluble liquid or solid mixtures in liquid at the molecular level

Filter powder, Crystallized powder, salt, sugar, ether sulphate, hydrolyzed colloid, CMC thixotrophy, rubber, natural or synthetic resin |

| Dispersed Suspension | Forms insoluble liquid or solid mixtures, mixtures with larger size pasticles or dispersed suspensions

Catalyst, pigment, graphite, paint coating, aluminum oxide, compound fertilizer, charcoal-ink agents, bactericide |

| emulsification | The situation where liquids that cannot be dissolved in a liquid solvent do not undergo phase separation.

Cream, Ice Cream, Animal Fat, Vegetable Oil, Protein, Silicone Oil, Mineral Oil, Paraffin |

| Homogeneity | Providing a more complete structure by reducing the particle sizes of suspended substances

Cream, Sweetener, Fruit Juice, Jam, Spreadable Cheese , Milk Oil , Toothpaste |

| Thick Liquid | Cell Tissue, Organic Tissue, Plant and Animal Tissue |

| Chemical Reaction | Nanometer material, high speed synthesis |

| extraction | Girsap extraction |

| Depolymerization | Nanometer powder, paste powder |

Reviews

There are no reviews yet.