![santrifuj-kapak[1]](https://inoksprom.com/wp-content/uploads/2024/02/santrifuj-kapak1.jpg)

![santrifuj-pompa5[1]](https://inoksprom.com/wp-content/uploads/2024/02/santrifuj-pompa51.png)

![santrifuj-pompa9[1]](https://inoksprom.com/wp-content/uploads/2024/02/santrifuj-pompa91.png)

![Resim2-1[1]](https://inoksprom.com/wp-content/uploads/2024/02/Resim2-11.png)

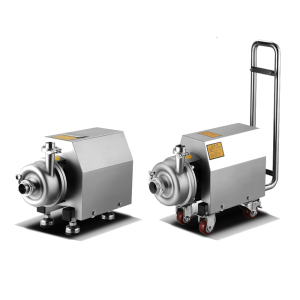

Centrifugal Breast Pump

- Description

- Reviews (0)

Description

Inoksprom Centrifugal Pump products; liquid foods; These are transfer units that enable transfer between the equipment that forms the process line.

In the industrialization process that our age is still in; As a result of the need to shorten the return period of investments, investors had to include increasing the operating capacity among their priority plans. Thus, solutions that can respond to high amounts of raw material input have emerged.

During the flow of liquids in the process line; It passes through many points that cause pressure drops, such as plate heat exchangers, filtering units, separators, elbow connection points and valves. Thus, there is a pressure difference, and therefore a flow rate difference, between the initial velocity of the liquid and its velocity after passing through any process equipment. Therefore, there is a need to use centrifugal pumps at more than one point on the process line.

In order not to damage the product and to ensure healthy and sustainable process conditions, correct pump selection is a critical point.

What is a Centrifugal Pump?

Research in the food process has focused on producing the same product with better quality, at lower costs and creating more comfortable process conditions. During the periods when liquid process lines were established under primitive conditions, fluids were mostly transferred from one point to another, from one machine to another, by the effect of gravity or through small-sized containers.

There are certain technical details to consider when choosing a centrifugal pump. Pump installations made without taking these parameters into consideration seriously affect the capacity and efficiency of other process equipment and, most importantly, product quality.

What Factors Should Be Considered When Choosing a Centrifugal Pump?

Chemical composition, % solid and water ratios of the product to be transferred

Heat

Viscosity

Intensity

Horizontal and vertical suction distances

Horizontal and vertical pressing distances

Pressure value in the process line

Diameter of installed pipeline

Centrifugal pumps; It is preferred as the most suitable solution for the transfer of liquid foods with high fluidity and low viscosity. If the viscosity value of the product exceeds a certain point, its performance decreases and in most cases it becomes unsuitable for use. When transferring products with viscosity problems, it is necessary to turn to MILKOSAN Positive Displacement / Lobe Pumps .

Liquids containing high amounts of gas or air bubbles in their structure, such as alcoholic and carbonated drinks, become difficult to transfer with a centrifugal pump and a decrease in performance values is observed. MILKOSAN Self Priming Pumps are suitable for these types of applications .

Centrifugal Pump Design

1: Pressing Line Connection

2 : Packing

3: Suction Line Connection

4 : Wheel

5 : Pump Housing

6 : Backplate

7 : Motor Shaft

8 : Engine

9 : Stainless steel cover/case

When designing centrifugal pumps; In addition to the technical details of the product and process line, the equipment between which the product is intended to be transferred should also be taken into consideration. Although providing product transfer in a straight pipeline brings with it an extremely simple design process, each of the flow line guiding fitting materials such as plate heat exchangers, elbows and distribution panels in the flow line directly affects the pressure value and therefore reduces the flow rate.

It may be necessary to integrate balance tanks at certain points to prevent flow rate problems caused by pressure differences. Moving from this point to a second centrifugal pumping process ensures the flawless and sustainable operation of the line.

While centrifugal pumps are positioned in the process line; It should be kept as close as possible to the storage tank or other feeding tanks. As few elbows and valves/fittings as possible in the suction line will minimize pressure difference formation and therefore performance change.

Installing a check valve at the discharge line connection point at the pump outlet is a measure that helps adjust the flow rate as needed while the pump is running and prevents the product from flowing backwards when the pump stops. For this purpose, simple analog type flow meters are integrated into the pump discharge line to monitor the flow rate instantly, and the same process can be achieved fully automatically via inverters.

Reviews

There are no reviews yet.